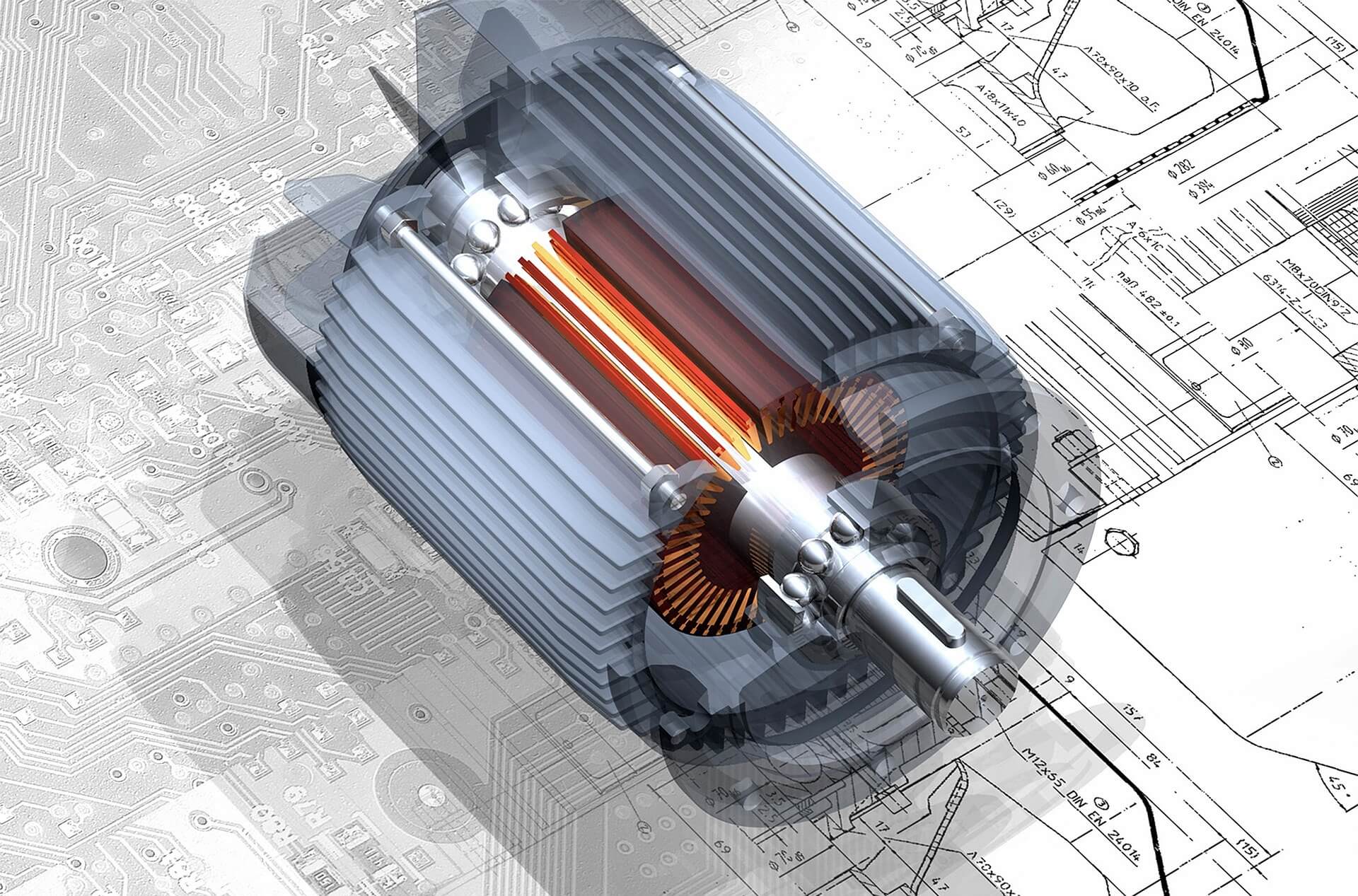

Popularly understood as 3D Rendering, it can easily be defined as the method of creating images digitally, based on the 3D data stored in your computer. However, in the context of mechanical engineering, Rendering is understood as the process of conversion of mechanical 3D models into photorealistic animations / pictures that seem as good as in real life.

In today’s world, 3D Rendering process is used by more than 90% of mechanical design engineers to create outstanding designs for product manufacturing. This increasing popularity of the use of 3D rendering is the sheer result of the quality of images / animations that are created through this method, be it their resolution, perfection, or unprecedented quality. The clarity od 3D rendered designs are just perfect for the engineers to visualize the outcome, allowing a sneak-peak into the final build of the product.

The recent technological breakthroughs have evenly changed the basic approach of engineers towards their projects. They are looking towards more effective and optimized processes to solve any given task. This is where the process of 3D rendering comes handy, as it yields superior outcomes.

Advantages of 3D Rendering:

- Cost effective

- Design Testing

- Optimized Workflow

- Better Presentation Capabilities

What makes up a good 3D Rendered Product Design:

- Appropriate references to geometric shading

- A proper description of the exact 3D model

- Proper light source specifications, position, orientation, etc.

- Instructions of the virtual camera positions

3D renders can be foreseen as the future of the mechanical design world, as it will keep transforming the realm of mechanical product design. However, a great deal of development is also anticipated in this field, mainly aimed at raising the standards of the software used and the procedures followed.